Experimental Petrology resources

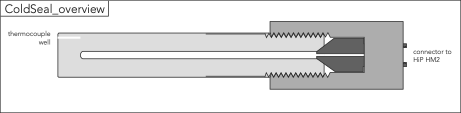

This design is a hybrid of vessel designs from the GeoForschungsZentrum in Potsdam and Macquarie University in Sydney with some additional modifications to fit our cold-seal system. The pressure connector sits within the collar for added safety. All parts have surplus length to allow for re-machining of cone and threads and prolong the life of the parts. The vessel connects to a HIP 9/16”-18 connector. The heated part of the vessel is made of the Ni-alloy Rene 41, but other alloys can be used, such as Nimonic 90 or Waspalloy. Nickel alloys provide great tensile strength and they fail by ballooning rather than fracturing, making them relatively safe to use in high pressure experiments. The collar is made of standard stainless steel 431 (DIN 1.4057), whereas the closure is made of the high-Cr steel Acidur (DIN 1.4122), which gives it chemical resistance to the hot pressure medium (generally water) at high pressure. The pressure vessel has a well for an external thermocouple. We have used this design up to 700˚C and 400 MPa for run durations of up to 6 weeks.

Cold-seal pressure vessels

I use a wide diversity of experimental equipment, most of which is custom-built or modified. At times, it can be quite the challenge to identify the right materials, locate suppliers, and draw the technical plans required to build and maintain an experimental petrology facility. This page is intended as a repository of this information. Feel free to use and share the technical drawings provided and if you would like to add some of your own, please get in touch.

The parts in the drawings posted here have been built and used, but we provide no guarantees as to their safety or suitability. All drawings for experimental parts and equipment should be evaluated by a qualified engineer.

This list is not exhaustive and represents only those suppliers from which we currently or in the past have sourced parts and materials.

Precious metals

Piston-cylinder supplies

-

• University of Oxford (piston-cylinder apparatus) - link

-

• Depths of the Earth (assemblies) - link

-

• SurePure Chemetals (lead foil) - link

-

• Professional Plastics (mylar insulating sheets) - link

-

• Omega (thermocouple wire) - link

Cold-seal pressure vessel parts

-

• Sitec (pressure generators, tubing, valves, connectors) - link

-

• HIP (pressure generators, tubing, valves, connectors) - link

-

• K&J Magnetics (magnets) - link

-

• Schmolz+Bickenbach (speciality steels including Acidur) - link

-

• Corpuscular (microspheres for fluid traps) - link

-

• SurePure Chemetals (nickel rods) - link

Controllers

-

• Omega (mass flow controllers, PIDU temperature controllers, data loggers) - link

-

• Eurotherm (thyristors, PIDU temperature controllers) - link

Sample preparation

Suppliers of experimental parts and consumables

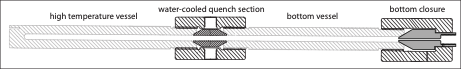

These drawings are for the high temperature vessel, the water-cooled quench section and the bottom vessel and closure. The sample capsule is held at the top of a sample holder that is magnetically levitated and moved up to the hot zone or down into the quench collar by moving an external magnet. We use Nimonic-90 and Waspalloy for the vessel exposed to high temperature, standard stainless steel 431 (DIN 1.4057) for all parts that are not in contact with the pressure medium (the quench collar and the bottom closure), and the high-Cr steel Acidur (DIN 1.4122, also known as Remanit) for the bottom cone given its high chemical resistance. The double cone in the quench assembly is made of Ampcoloy 944 Cu-alloy. Copper was chosen because of its rapid removal of heat, and this Ampcoloy 944 is hard enough to avoid deformation that would reduce the inner diameter. Beryllium-copper would be better, but few workshops are able to machine this because of the toxicity of Be. A well is present in the top vessel for a thermocouple. The vessel has a HIP 9/16”-18 connector for the pressure medium and two 1/4” NPTF connectors for coolant water circulation.

Rapid quench cold-seal pressure vessel system

The technical drawings below are for the water-cooled closures that make the gas-tight seal on the alumina tube in a 1-atm controlled-gas-atmosphere tube furnace. Cooling water circulates in a copper tubing loop that fits snuggly in the main brass body of the closure and cools the rubber O-rings that make the seal. We use thick-walled extruded tubing instead of welded tubing to minimize the chances of rupture. We have a number of interchangeable aluminium end discs with different sized ports to allow for a variety of experiments. Gasses are fed centrally through the bottom end closure and vent from the side at the top closure. The system allows for quenching by pulling the sample out from the top, or drop quenching.

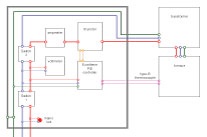

The second drawing shows the electrical layout of the temperature controller for our 1-atm furnace. The main components are a PIDU controller coupled to a thyristor.

Controlled gas atmosphere furnace

Ore crusher, Botswana