Our lab

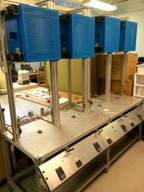

FlexPet Lab

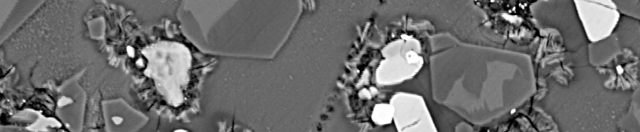

The cold-seal hydrothermal pressure vessels are the workhorse of the lab and are used in mineral synthesis, water-rock interaction and element partitioning experiments, amongst others. We have a manually-operated, custom-built system of two vessels capable of 400 MPa at up to 650˚C and an automated 4-vessel LECO system that can operate up to 200 MPa and temperatures up to 950˚C. Both use water as the pressure medium and are quenched by compressed air at the end of an experiment. Vessels are made of Rene 41 Ni-alloy. In typical experiments, the starting material is sealed in an inert metal capsule, which is placed at the hot end of the vessel, held in place with a Ni rod. The vessel is pressurized and subsequently heated isobarically to the run temperature. Experiments can last from minutes to months. Runs are quenched by rapidly cooling the vessel under isobaric conditions by compressed air.

Cold-seal hydrothermal pressure vessels

The experimental equipment in our laboratory allows for simulation of conditions found at the surface of the Earth to deep in its interior. We can access temperatures from 0 to 1800˚C and pressures from 0.1 MPa (1 bar) to 3 GPa (30 kbar) at controlled compositions and gas atmospheres. The experimental facility is supported by a sample preparation lab with box furnaces, a PUK arc welder and microscope.

The lab is used by my group and the Magma Degassing group, led by Prof. Kim Berlo, but is open to external users. If you would like to conduct experiments in our facility, please get in touch with me for any experiments involving fluids or partitioning, and Kim Berlo for experiments involving melts.

The rapid-quench system uses a similar experimental technique to the standard cold-seal vessels, but can achieve a very fast quench by dropping the experimental capsule into a water-cooled sleeve at the end of the experiment. We have a four-vessel rapid-quench system, which is water pressurized and can be operated to 950˚C at 200 MPa or 1050˚C at 100 MPa. Temperatures and pressures are continuously monitored and recorded. This system is mainly used in melt experiments and mineral-melt partitioning studies, because it can reach higher temperatures and provides the ability to rapidly quench melts to glass. By connecting a rapid quench vessel to one of our standard cold-seals, we can run controlled decompression experiments, which is of particular interest in studies of magma degassing.

Rapid-quench cold-seal pressure vessels

Our 1-atmosphere Gero furnace is capable of operating at temperatures up to 1800˚C, and is mainly used to prepare starting glasses for experiments and to run partitioning experiments between melts and minerals in model systems. The furnace encloses an inert and gas tight alumina-ceramic tube in which a controlled gas atmosphere can be created. This allows us to control the oxygen fugacity in the furnace, or introduce SO2, N2 or CO2. Experiments can be in sealed inert capsules, in open large or small volume crucibles, or suspended from wire loops. We also run experiments where the crucible material reacts with the experimental charge to study, for example, reactions between melts and their host rocks. When open experimental containers are used, we can induce reactions by changing the gas composition. We can also run DTA (Differential Thermal Analysis) experiments in the furnace, where we determine the thermal energy released or consumed in reactions during the experiment. DTA works by measuring the small differences in temperature between the experiment undergoing a reaction and an adjacent, equivalent, but empty reference. This can be used, for example, to determine the enthalpy of melting or decarbonation. Experiments are quenched by dropping them into a cold oil bath, or by simply pulling them out of the furnace.

1-atmosphere furnace with controlled gas atmosphere

For higher pressure experiments, we have an end-loaded piston-cylinder apparatus. Our system is designed for lower pressure but large-volume experiments, but can also accommodate a smaller volume cell to reach maximum pressures of 3 GPa (30 kbar). An experimental charge in an inert metal capsule (commonly, Pt, Au or Ag) is enclosed in a pressure medium that will readily deform during pressurization and ensure that the experiment is close to being pressurized uniformly from all directions (NaCl is used in our fluid experiments). This in turn is placed in a graphite cylinder, which acts as the internal furnace during the run, separated from the metal cylinder by an outer pressure medium sleeve. A hydraulically operated piston pressurizes the sample. Temperature is monitored continuously using a thermocouple that is inserted into the experimental assembly and positioned just above the capsule. Experiments are quenched by cutting the power to the graphite heater.

End-loaded piston-cylinder

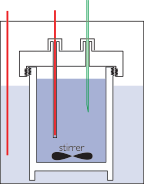

We also conduct experiments at near-surface conditions and for these we use a series of closed-volume autoclaves and a flow-though cell. The flow-though cell is a large volume teflon container with a number of ports that allow for material (gas or liquid) to be added or extracted during the run, and for a variety of parameters to be monitored, such as pH and temperature. The vessel is externally heated and can be stirred. It is used to synthesize minerals, to study mineral precipitation in hydrothermal systems, or to conduct partitioning studies at low temperature and varying under reaction kinetics. Our current system can be used from 0 to 120˚C. Closed-volume hydrothermal vessels are used for higher temperatures, up to 400˚C, after which we switch to the cold-seals. Pressure is generated internally by the experimental solution and can be at, above, or below vapour-saturation depending on fill volume. The large volume of the autoclaves allows for adding traps to sample material during the run or upon quenching (for example the vapour phase). An internal capsule with a buffer can also be added.

Hydrothermal and flow-through autoclaves